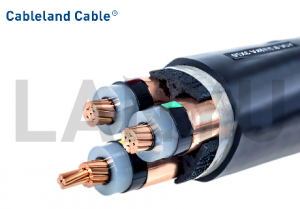

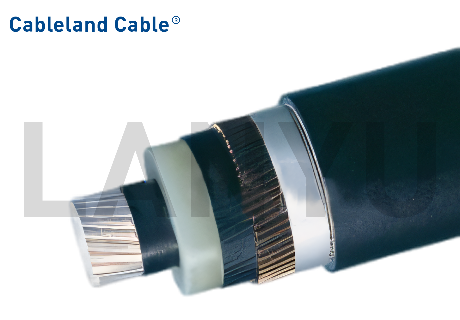

This product is suitable for 6kv-35kv power transmission and distribution system to transmit electric energy. It has the characteristics of light weight and moisture resistance, and can be laid in indoor and outdoor environment such as direct burial, Cable bridge, Pipe, support, cable trench, etc.

Working temperature and laying conditions

- Rated power frequency voltage U0 / U6 / 6kv-26 / 35kV.

- The maximum allowable long-term temperature of cable conductor shall not exceed 90 ℃.

- The maximum temperature of cable conductor shall not exceed 250 ℃ in case of short circuit (the longest time shall not exceed 5S).

- The ambient temperature during cable laying shall not be lower than 0 ℃.

Cable bending radius:

- Single core cable: 20D

- Three core cable: 15D

Product features

(1) Electrical performance

The conductivity of medium voltage aluminum alloy cable is between aluminum and copper. Under the same current carrying capacity, the weight of aluminum alloy conductor with the same length is only half of that of copper conductor. When the cross-sectional area of aluminum alloy conductor is 1.5 times of that of copper, its electrical performance is the same, that is, it achieves the same current carrying capacity, resistance and voltage loss as copper.

(2) Creep resistance

The medium voltage aluminum alloy conductor is added with iron, copper, zinc, magnesium, rare earth and other metal elements, and the unique heat treatment process greatly reduces the “creep” tendency of metal under heating and pressure. Especially when the alloy element is added during the annealing of the conductor, it has high creep resistance, which can ensure the stability of the connection even when it is overloaded and overheated for a long time.

(3) Connection performance

The connection performance of medium voltage aluminum alloy cable and fittings has passed 1000 times of thermal cycle test, which proves that the long-term stability and reliability of aluminum alloy cable connection is the only basis for judging the connection quality.

(4) Corrosion resistance

A dense oxide film with a thickness of about 2×10-4mm is formed in the air to prevent further corrosion of the inner metal. The addition of cerium, lanthanum and other rare earth elements in the aluminum alloy conductor further improves the corrosion resistance of the metal materials with aluminum as the conductor. The corrosion resistance of aluminum alloy is much better than that of copper in sulfur-containing environment.

(5) Mechanical properties

High elongation: the elongation of aluminum alloy conductor can reach more than 30%, which is an important symbol of the product quality and the ability to withstand external force.

Strength and toughness: the flexibility of aluminum alloy is 25% higher than that of copper. Even if it is repeatedly stressed, it will not produce cracks, reducing the potential safety hazards in the installation process.

Easy to bend: the minimum bending radius of aluminum alloy cable is 7 times the outer diameter of the cable, which reduces the installation layout space, makes it easier to lay, and saves the installation cost.

Low bounce: the bounce angle of aluminum alloy cable is 40% smaller than that of copper cable, which is more conducive to the tightness of terminal connection joint, easy to compress and improve the stability of connection.

Related products