Copper cable transmission can achieve a long distance, that is, the power supply covers a large area, which is conducive to network planning and reducing the number of power supply points.

Copper Medium Voltage Cable has low resistivity, good ductility, and its allowable stress at room temperature is 7 ~ 28% higher than that of aluminum. Especially under the stress of high temperature, copper cable is resistant to oxidation and corrosion. Due to the low resistivity of copper cable, the voltage drop of copper cable is small when the same current flows through the same section. Therefore, the same transmission distance can ensure higher voltage quality.

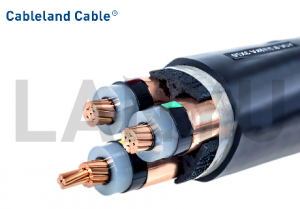

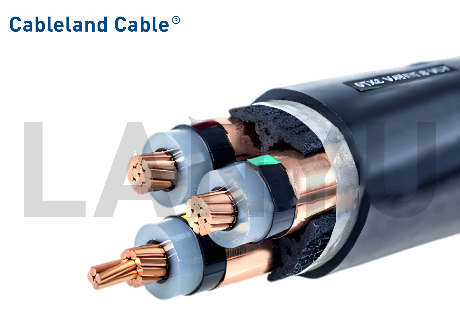

Advantages of copper cable

- The resistivity is low and the conductivity of copper is good.

- Good ductility, not very hard.

- High strength: the allowable stress at room temperature is relatively high, especially at high temperature.

- Anti fatigue

- Good stability, corrosion resistance: copper core oxidation resistance, corrosion resistance.

- High current carrying capacity: because of low resistivity.

- Low voltage loss: because the resistivity of copper core cable is low, the same current flows through the same section. The voltage drop of copper core cable is small. The same transmission interval can ensure higher voltage quality; Under the allowable voltage drop condition, the copper core cable transmission can reach a long distance, that is, the power supply coverage area is large, which is conducive to network planning and reducing the number of power supply points.

- Low heating temperature: under the same current, the heating capacity of copper core cable with the same section is much smaller than that of aluminum core cable, which makes the operation safer.

- Low energy consumption: because the resistivity of copper is low, compared with aluminum cable, the power loss of copper cable is low, which is clear. This is conducive to improving the utilization rate of power generation and protecting the environment.

- Oxidation resistance, corrosion resistance: copper cable connector function is stable, will not be because of oxidation and trouble. The joint of the aluminum core cable is not stable, and the touch resistance is often increased due to oxidation, resulting in fever. Therefore, the incident rate is much higher than that of copper core cable.

Model description of Copper MV Cable

| VV | PVC insulated vinyl chloride sheathed power cable |

| VY | PVC insulated PE sheathed power cable |

| VV22 | PVC insulated steel belt can be used to install PVC sheathed power cable |

| VV23 | PVC insulated steel belt can be used to install PE sheathed power cable |

| VV32 | PVC sheathed power supply with vinyl chloride insulation |

| VV33 | Vinyl chloride insulation can be used to install polyethylene sheathed power supply |

| YJV | XLPE insulated PVC sheathed power cable |

| YJV | XLPE insulated PE sheathed power cable |

| YJV22 | XLPE insulated steel belt armored PVC sheathed power cable |

| YJV23 | XLPE insulated steel belt armored PE sheathed power cable |

| YJV32 | XLPE insulated fine steel wire armored PVC sheathed power cable |

| YJV33 | XLPE insulated thin steel wire armored PE sheathed power cable |

Related products