All aluminum alloy Conductor (AAAC) Definition: All strands are stranded wires of aluminum alloy wire.Since it was put into production in 2008, the product quality has been relatively stable, the production efficiency is high, and the market share is high in the international market.

AAAC has high strength and good sag characteristics. AAAC is 21% ~ 26% lighter than ACSR, and its deformation tension is 21% ~ 23% lower. The tensile strength of AAAC is 1.7 ~ 1.8 times that of ordinary conductor. The ratio of total breaking force to weight per unit length of high strength all aluminum alloy stranded wire without strip core is more than 10km, which is higher than that of reinforced steel cored wire in the past (about 9km). Therefore, it can effectively reduce the height of the tower, or increase the erection spacing, and reduce the project investment.

Advantage:

- AAAC has large mechanical resistance than AAC which permits its use as a bare overhead conductor on aerial circuits for power transmission and distribution lines.

- AAAC has better sag characteristics and strength to weight ratio as compared to AAC.

- AAAC weight per unit and resistance is also lower which gives it advantage over the ACSR. Also, AAAC conductor has better corrosion protection than ASCR conductors.

AAAC All Standard

BS 3242

| Code Name | Nominal Area (mm²) | Stranding (No./mm) | Diameter Of Conductor (mm) | Linear Mass (kg/km) | Rated Strength (kgf) |

| Box | 15 | 7/1.85 | 5.55 | 51 | 537 |

| Acacia | 20 | 7/2.08 | 6.24 | 65 | 680 |

| Almond | 25 | 7/2.34 | 7.02 | 82 | 861 |

| Cedar | 30 | 7/2.54 | 7.62 | 97 | 1014 |

| 35 | 7/2.77 | 8.31 | 115 | 1205 | |

| Fir | 40 | 7/2.95 | 8.85 | 131 | 1367 |

| Hazel | 50 | 7/3.30 | 9.9 | 164 | 1711 |

| Pine | 60 | 7/3.61 | 10.83 | 196 | 2048 |

| 70 | 7/3.91 | 11.73 | 230 | 2402 | |

| Willow | 75 | 7/4.04 | 12.12 | 245 | 2565 |

| 80 | 7/4.19 | 12.57 | 264 | 2758 | |

| 90 | 7/4.44 | 13.32 | 298 | 3112 | |

| Oak | 100 | 7/4.65 | 13.95 | 325 | 3398 |

| 100 | 19/2.82 | 14.1 | 326 | 3393 | |

| Mulberry | 125 | 19/3.18 | 15.9 | 415 | 4312 |

| Ash | 150 | 19/3.48 | 17.4 | 497 | 5164 |

| Elm | 175 | 19/3.76 | 18.8 | 580 | 6030 |

| Poplar | 200 | 37/2.87 | 20.09 | 659 | 8841 |

| 225 | 37/3.05 | 21.35 | 744 | 7724 | |

| Sycamore | 250 | 37/3.22 | 22.54 | 835 | 8664 |

| Upas | 300 | 37/3.53 | 24.71 | 997 | 10350 |

| Walnut | 350 | 37/3.81 | 26.67 | 1162 | 12053 |

| Yew | 400 | 37/4.06 | 28.42 | 1319 | 13685 |

| Totara | 425 | 37/4.14 | 28.98 | 1372 | 14233 |

| Rubus | 500 | 61/3.50 | 31.5 | 1620 | 16771 |

| Araucaria | 700 | 61/4.14 | 37.26 | 2266 | 23450 |

DIN 48201

| Nominal area (mm^2) | actual area (mm^2) | Stranding (No.xmm) | Overall Diameter (mm) | Weight (kg/km) | Rated Strength (KN) | Electrical Resistance (Ω/Km) | Current Rating* (A) |

| 16 | 15.89 | 7/1.70 | 5.1 | 43 | 4.44 | 2.0742 | 78 |

| 25 | 24.25 | 7/2.10 | 6.3 | 66 | 6.77 | 1.3593 | 102 |

| 35 | 34.36 | 7/2.50 | 7.5 | 94 | 9.6 | 0.9591 | 126 |

| 50 | 49.48 | 7/3.00 | 9 | 135 | 13.82 | 0.666 | 158 |

| 50 | 48.35 | 19/1.80 | 9 | 133 | 13.5 | 0.6849 | 156 |

| 70 | 65.81 | 19/2.10 | 10.5 | 181 | 18.38 | 0.5032 | 189 |

| 95 | 93.27 | 19/2.50 | 12.5 | 256 | 26.05 | 0.3551 | 234 |

| 120 | 116.99 | 19/2.80 | 14 | 322 | 32.68 | 0.2831 | 269 |

| 150 | 147.11 | 37/2.25 | 15.8 | 406 | 41.09 | 0.2256 | 309 |

| 185 | 181.62 | 37/2.50 | 17.5 | 500 | 50.73 | 0.1828 | 352 |

| 240 | 242.54 | 61/2.25 | 20.3 | 670 | 67.74 | 0.1371 | 420 |

| 300 | 299.43 | 61/2.50 | 22.5 | 827 | 83.63 | 0.111 | 477 |

| 400 | 400.14 | 61/2.89 | 26 | 1104 | 111.76 | 0.0831 | 568 |

| 500 | 499.83 | 61/3.23 | 29.1 | 1379 | 139.6 | 0.0665 | 649 |

| 625* | 626.2 | 91/2.96 | 32.6 | 1732 | 174.9 | 0.0531 | 742 |

| 800* | 802.09 | 91/3.35 | 36.9 | 2218 | 224.02 | 0.0415 | 857 |

| 1000* | 999.71 | 91/3.74 | 41.1 | 2767 | 279.22 | 0.0333 | 971 |

BS EN50182

| Code | Stranding (No.xmm) | Nominal Area (mm^2) | Overall Diameter (mm) | Weight (kg/km) | Rated Strength (KN) | Electrical Resistance (Ω/Km) | Current Rating* (A) |

| Box | 7/1.85 | 18.8 | 5.55 | 51.4 | 5.55 | 1.748 | 87 |

| Acacia | 7/2.08 | 23.8 | 6.24 | 64.9 | 7.02 | 1.3828 | 101 |

| Almond | 7/2.34 | 30.1 | 7.02 | 82.2 | 8.88 | 1.0926 | 116 |

| Cedar | 7/2.54 | 35.5 | 7.62 | 96.8 | 10.46 | 0.9273 | 129 |

| Deodar | 7/2.77 | 42.2 | 8.31 | 115.2 | 12.44 | 0.7797 | 143 |

| Fir | 7/2.95 | 47.8 | 8.85 | 130.6 | 14.11 | 0.6875 | 155 |

| Hazel | 7/3.30 | 59.9 | 9.9 | 163.4 | 17.66 | 0.5494 | 178 |

| Pine | 7/3.61 | 71.6 | 10.83 | 195.6 | 21.14 | 0.4591 | 199 |

| Holly | 7/3.91 | 84.1 | 11.73 | 229.5 | 24.79 | 0.3913 | 219 |

| Willow | 7/4.04 | 89.7 | 12.12 | 245 | 26.47 | 0.3665 | 228 |

| Oak | 7/4.65 | 118.9 | 13.95 | 324.5 | 35.07 | 0.2767 | 272 |

| Mulberry | 19/3.18 | 150.9 | 15.9 | 414.3 | 44.52 | 0.2192 | 314 |

| Ash | 19/3.48 | 180.7 | 17.4 | 496.1 | 53.31 | 0.183 | 351 |

| Elm | 19/3.76 | 211 | 18.8 | 579.2 | 62.24 | 0.1568 | 386 |

| Poplar | 37/2.87 | 239.4 | 20.09 | 659.4 | 70.61 | 0.1387 | 416 |

| Sycamore | 37/3.23 | 303.2 | 22.61 | 835.2 | 89.4 | 0.1095 | 480 |

| Upas | 37/3.53 | 362.1 | 24.71 | 997.5 | 106.82 | 0.0917 | 535 |

| Yew | 37/4.06 | 479 | 28.42 | 1319.6 | 141.31 | 0.0693 | 633 |

| Totara | 37/4.14 | 498.1 | 28.98 | 1372.1 | 146.93 | 0.0666 | 648 |

| Rubus | 61/3.50 | 586.9 | 31.5 | 1622 | 173.13 | 0.0567 | 714 |

| Sorbus | 61/3.71 | 659.4 | 33.39 | 1822.5 | 194.53 | 0.0505 | 764 |

| Araucaria | 61/4.14 | 821.1 | 37.26 | 2269.4 | 242.24 | 0.0406 | 868 |

| Redwood | 61/4.56 | 996.2 | 41.04 | 2753.2 | 293.88 | 0.0334 | 970 |

NFC 34125

| Code Name | Actual section (mm²) | No. of wire | Wire diameter (mm) | Conductor diameter (mm) | Conductor weight appr. (kg/km) | Calc. breaking force (kN) | Conductor resistance at 20°C (Ohm/km) |

| ASTER 22 | 21.99 | 7 | 2 | 6 | 60.2 | 7.15 | 1,498 |

| ASTER 34.4 | 34.36 | 7 | 2.5 | 7.5 | 93.5 | 11.17 | 0.959 |

| ASTER 54.6 | 54.55 | 7 | 3.15 | 9.45 | 148.9 | 17.73 | 0.604 |

| ASTER 75.5 | 75.54 | 19 | 2.25 | 11.3 | 207.4 | 24.55 | 0.438 |

| ASTER 117 | 116.98 | 19 | 2.8 | 14 | 321.2 | 38.02 | 0.283 |

| ASTER 148 | 148.01 | 19 | 3.15 | 15.8 | 406.6 | 48.12 | 0.223 |

| ASTER 181.6 | 181.62 | 37 | 2.5 | 17.5 | 500.3 | 59.03 | 0.183 |

| ASTER 228 | 227.83 | 37 | 2.8 | 19.6 | 627.6 | 74.04 | 0.146 |

| ASTER 288 | 288.34 | 37 | 3.15 | 22.1 | 794.3 | 93.71 | 0.115 |

| ASTER 366 | 366.22 | 37 | 3.55 | 24.9 | 1.008.9 | 115.36 | 0.09 |

| ASTER 570 | 570.22 | 61 | 3.45 | 31.1 | 1.576.0 | 185.33 | 0.058 |

| ASTER 851 | 850.66 | 91 | 3.45 | 38 | 2.360.7 | 276.47 | 0.039 |

| ASTER 1144 | 1143.5 | 91 | 4 | 44 | 3.173.4 | 360.22 | 0.029 |

| ASTER 1600 | 1595.9 | 127 | 4 | 52 | 4.427.5 | 502.72 | 0.021 |

According to the French experience, the span is increased from 350m-400m to 550m, and the construction investment can be saved by 5% – 8% if the high-strength all aluminum alloy wire is used instead of ACSR in the new line;

High conductivity, large transmission capacity and small line loss. The conductivity of AAAC is 6% ~ 11% higher than that of corresponding ACSR, with lower AC impedance and 3% less line loss. When the ACSR is replaced by AAAC, the capacity of the transmission line can be increased without any modification or enhancement of the original supporting tower;

Good corrosion resistance. The steel strand in ACSR has the problem of electric corrosion in operation, especially in the polluted area. The aluminum alloy monofilament used by AAAC is more corrosion-resistant than ordinary aluminum, and AAAC has no steel core, so there is no electric corrosion problem of steel wire;

The surface is resistant to damage. The hardness of the aluminum alloy wire is twice that of the aluminum wire, which can reduce the surface scratch of the wire, improve the construction quality, and reduce the corona loss and radio interference level;

Good creep resistance, high elongation and high temperature characteristics. According to the standard value, the elongation of aluminum wire is 2 times of that of aluminum wire (1.5%), and the actual test value can reach 7% ~ 8%. It has excellent overload capacity and fatigue characteristics. At high temperature, the strength loss is small, and the high temperature operation plays the role of artificial aging, increasing the conductivity by 2% ~ 5%;

Good connectivity, simple and convenient connection. Large torque can be used without considering the cold deformation of conductor;

Compared with ACSR, AAAC has no steel core and is of the same material. Its recyclability is greatly improved and its recycling rate is high, which is beneficial to environmental protection.

Related products

AAC Cable/ All Aluminum Conductor

Click For Latest Price

AAAC / All Aluminum Alloy Conductor

Click For Latest Price

ACAR / Aluminum Conductor Alloy Reinforced

Click For Latest Price

ACSR / Aluminum Conductor Steel Reinforced

Click For Latest Price

AACSR / All aluminum Alloy Conductor Steel Reinforced

Click For Latest Price

Galvanized Steel Wire / Galvanized Steel Stand

Click For Latest Price

Our customers have covered more than 60 countries. Export regions include Europe, North America, North Africa, Middle East, Southeast Asia, etc.

We provide seaworthy cable packing, wooden drum/wooden-steel drum/ steel drum and etc, cable length can be designed according to customer needs.

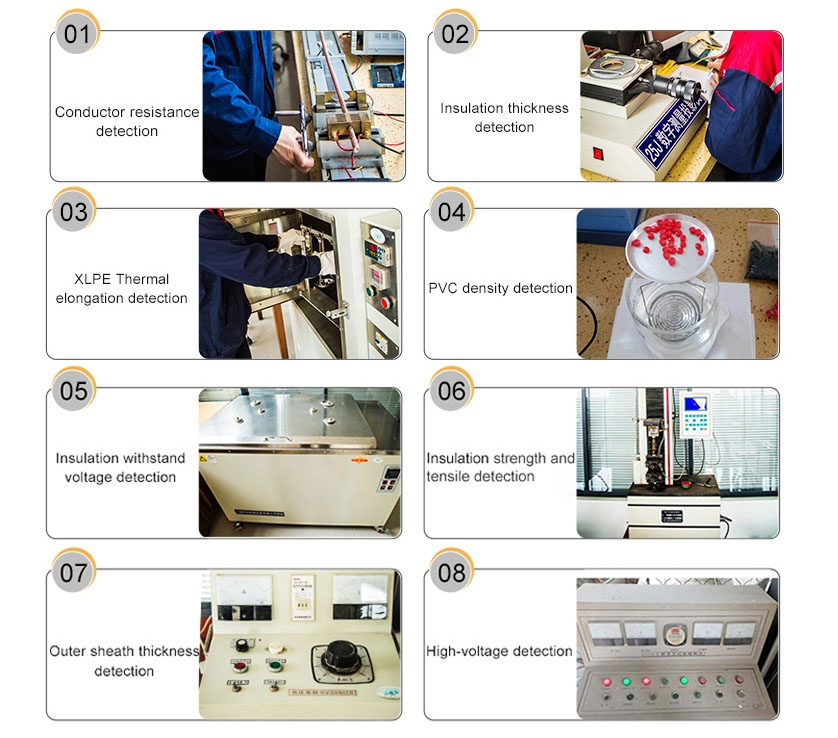

We have a complete quality control system, advanced laboratory equipment, to ensure that every batch of goods sent to customers meets the quality requirements. Meanwhile, we accept testing requirements from customers and third-party testing agencies.

We believe that an excellent professional team is the best guarantee for quality service!